Considerations in the Design of an Operating Room Behavior Management System

1. The Past and Present of the Operating Room Behavior Management System

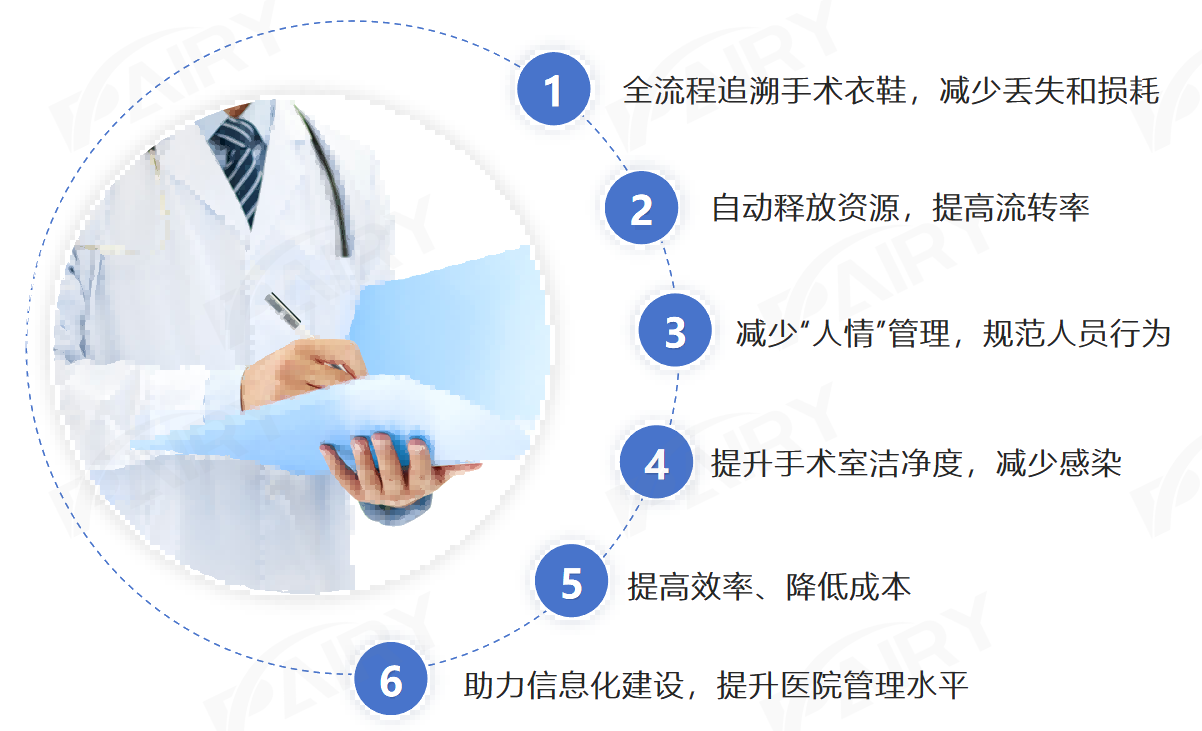

When discussing smart operating room-related solutions, it is inevitable to address digital operating rooms and operating room behavior management systems. Unlike digital operating rooms, which originated abroad, the operating room behavior management system is a homegrown product: it emerged around 2015 and gradually expanded within major tertiary hospitals in China after 2018. Today, it has become an essential system for newly built tertiary hospital operating rooms in China, extending its reach to secondary hospitals, while retrofitting existing facilities has also become a trend.As for the functions of the Operating Room Behavior Management System, they are already well-known among professionals in healthcare informatization and the relevant departments of hospitals. Its core functions include: implementing access control management for medical staff, intelligent dispensing, storage, and recycling of surgical gowns and shoes with full-process traceability, establishing an intelligent management system for staff behavior, reducing violations, lowering the loss rate of gowns and shoes, improving equipment turnover rates, and ultimately ensuring infection control requirements in the operating room while enhancing management levels and operational efficiency. Some manufacturers have expanded to include additional auxiliary functions such as electronic fencing, staff area positioning, and hand hygiene monitoring, which will not be elaborated on here. The focus will instead be on the key considerations in its design process, aiming to provide relevant reference suggestions for design institutes, general contractors, hospital infrastructure departments, information technology departments, and others.

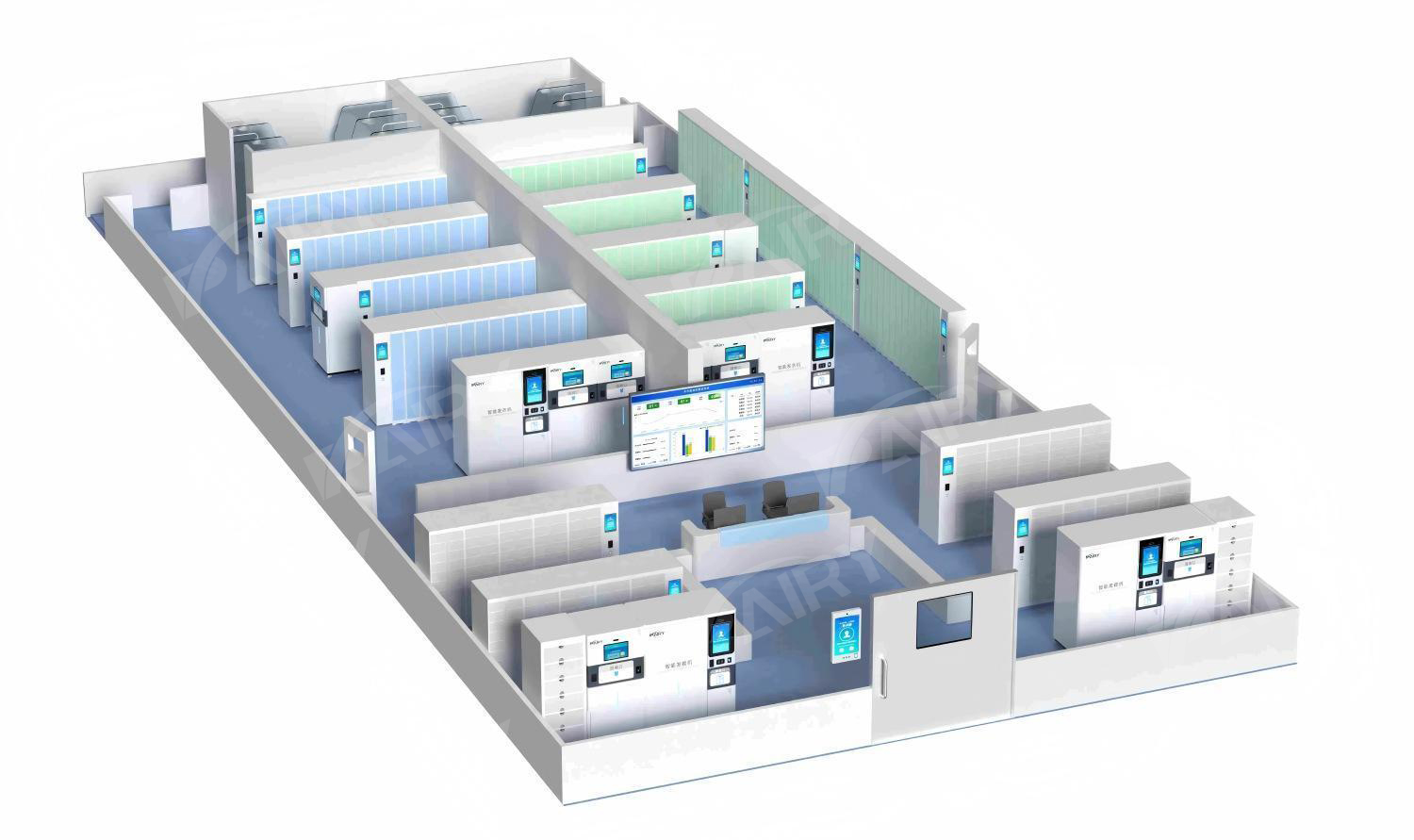

2. Main Hardware Components of the System

The system mainly includes the following hardware components:1. Intelligent Access Control System

2. Intelligent Uniform Dispensing Machine / Shoe Dispensing Machine

3. Intelligent Locker for Clothing/Shoes

4. Intelligent Clothing Collection Machine / Shoe Collection Machine

5. Mask and Cap Dispensing Cabinet

6. Outdoor Clothing Cabinet, Temporary Storage Locker

7. Shoe Cleaning Machine, Disinfection Cabinet, etc

8. Servers, Workstations, Announcement Display Screens, Registration/Data Entry Devices, and Other Peripherals

3. Key Considerations During the Design Process

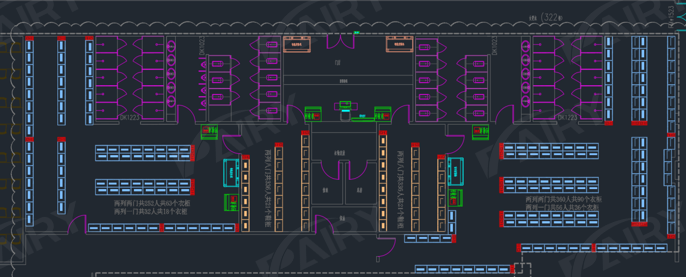

1. Quantity Planning/DesignBased on 8 to 10 staff members per surgery, and taking into account nursing staff, external personnel, and some reserve capacity, newly built hospitals generally plan for 15 people per operating room, while some large hospitals may accommodate up to 20 people per operating room. A simple calculation formula is: Number of intelligent clothing/shoe lockers = Number of operating rooms × 15–20. For example, a newly built tertiary hospital with 30 operating rooms would reserve capacity for 450–600 people. Of course, a key factor to consider is whether the locker room area is sufficient. When the locker room area is sufficiently large, more single-layer lockers can be planned, offering greater storage space and more convenient placement for lab coats. If the area is limited, double-layer or even triple-layer lockers can be prioritized. As for shoe lockers, 6-layer or 8-layer cabinets are commonly used, with some 4-layer shoe lockers reserved for storing women's long boots.

2. Power and Low-Current Pre-wiring and Power Capacity

Each main control device (including the uniform dispenser, shoe dispenser, main clothing/shoe control cabinet, and recycling machine) requires pre-wired connections for one strong-current circuit and one low-current circuit—specifically, a 220V power outlet and a network outlet. It is recommended that the power and network outlets for the main clothing/shoe control cabinet be placed 5–10 cm above the cabinet. For example, if the cabinet height is 1.95 meters, positioning the outlets at around 2 meters is appropriate. Outlets for other devices can be designed at the conventional height of 30 cm above the floor. For dispensing and recycling equipment, a power capacity of around 200W should be reserved. For the main clothing/shoe cabinet, a power capacity of 50–100W is sufficient. Sub-cabinets can be daisy-chained to the main cabinet, and their power consumption can be considered negligible.

(The image above shows the behavioral management design layout of a certain hospital.)

4. Color SelectionIt is recommended to choose soft and elegant color schemes for clothing and shoe lockers, such as light blue, sky blue, light green, or light gray. For women's locker rooms, light purple or pink can also be considered, based on personal preference. Ideally, selection should be guided by the manufacturer's past cases or photos. Relying solely on color codes or swatches may lead to discrepancies due to lighting effects or large-scale placement, both of which can impact the desired outcome.

Attached are some case studies of outstanding hospitals to share with everyone.

(Taken from the WeChat official account "Smart OR")